Or we may want to do without the C-clamps by bolting the modules together such that they align the way we want them to each time we set them up. The key to this kind of a setup is a threaded bolt slid through a T-nut on one module and threaded into a matching T-nut in the other module. All we have to do is to tighten the bolt with a wrench, ratchet-and-socket, or nut-driver.

Modifying T-nuts For Alignment Bolts & Pins

The first step is to drill the threads out of two T-nuts so that a 5/16" bolt will easily slide through one T-nut but thread into a mating T-nut.

1) Clamp a T-nut into your bench vice with the "washer" part of the T-nut up. Make sure the T-nut and the vice are securely clamped!

2) Drill the threads out of the T-nut with a 5/16" drill bit. Be careful! The drill bit will grab the threads and try to twist the drill out of your hands! In the photo below you should be able to see two T-nuts with the thread drilled out.

3) Once you've drilled out the threads, you have what I call a "blind" T-nut. Remove the T-nut with a pair of pliers - the T-nut will be extremely hot! Make sure the bolt freely slides through the "blind" T-nut.

4) Drill the threads out of the next T-nut.

5) In order not to mix up these "blind" T-nuts, I paint the washer part and their corresponding bolts with red paint as shown in the photo below so that they'll be obvious when I scramble underneath a completed module set to bolt them together. (I've made a couple of extra "blind" T-nuts for another module.)

Marking the End-Plates For Alignment Pins/Bolts

Now that we've modified two of the T-nuts so that a bolt will easily slide through them, it's time to prepare the end plates in a way that ensures our two modules will align together in the same place each time we clamp them together. To do this, we complete the following steps.

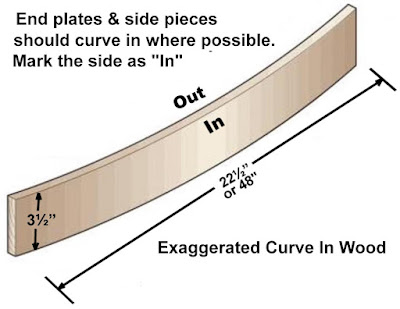

1) Place the end plate of Module #1 and the corresponding end plate of Module #2 on your work surface with the "Top" down (or "Bottom" up) and the "In" side facing you. (Or to state it another way, the "Out" sides should both be in.)

2) Make sure the "Top" edge of Module #1 is flush and even with the "Top" edge of Module #2.

3) Clamp both end plates together with clamps at each end.

4) Drill and countersink a screw hole at each end.

5) Insert and screw in a 1" flat-head wood screw in both ends so that, when we remove the clamps, the two end pieces will be securely fastened.

This is what the two carry plates should look like.

Locate & Drill Holes For Alignment Pins/Bolts

Now that we've got the end plate of Module #1 lined up with the end plate of Module #2, we're ready to locate and drill the holes for the "blind" and threaded T-nuts.

In positioning these T-nuts, we have to make sure we have enough clearance underneath the modules so that our wrenches (socket, nut driver, etc) won't be obstructed by the gussets or the Styrofoam. For the modules I'm building, I find that the dimensions shown below - 6" from each end plate and 2 1/2" down from the top - will do the job. If you're using different widths of lumber or different thicknesses of Styrofoam, you'll have to adjust these measurements accordingly.

1) Measure 6" from both ends and 2 1/2" down from the "Top".

2) Drill a 1/8" pilot through both end plates at each end.

3) Countersink the two pilot holes in the end plate of Module #1 by 1/8" using a 1" Forstner bit or a 1" spade bit so that the "washer" part of the T-nut is below the surface of the wood.

4) Flip the end plates over and repeat Step 3) for Module #2.

5) Drill a 3/8" hole through both end plates at each end.

6) Make sure the barrel of the T-nut fits snugly in all 4 holes.

7) Keep both end plates screwed together!

Installing Blind & Threaded T-nuts

We're now ready to install the "blind" and threaded T-nuts for our alignment pins/ bolts.

So far we've installed T-nuts for the corner gussets and the carry plates. Installing "blind" and threaded T-nuts for alignment pins/ bolts is no different. We just have to keep our eyes open for a couple of things.

The end plate of Module #1 should still be screwed to the end plate of Module #2. (Pssst. Don't tell anyone but that's the secret in ensuring that both modules will properly line up with each other when we bolt them together!)

We gather the same materials and tools that we used for previous T-nut installations. This time we will use a 1 1/2"x 5/16" bolt to torque the T-nuts into place.

1) Make sure you have 2 "blind" T-nuts and 2 threaded T-nuts.

2) Load the barrel of a "blind" T-nut with epoxy and insert it in one of the drilled holes for Module #1.

3) Load the barrel of a threaded T-nut with epoxy and insert it on the opposite side of Module #2.

4) Insert the 1 1/2 bolt through the "blind" T-nut and thread it into the threaded T-nut until it's finger tight (now you know why we painted the "blind" T-nut red, eh!?)

5) Using a 1/2" wrench (ratchet & socket, nut driver, etc), torque the T-nuts into place until they are snugly tight.

6) Remove the 1 1/2" threaded bolt.

7) If I'm using bolts to connect Module #1 to Module #2, I prefer to alternate the "blind" T-nuts. That is, one blind T-nut will be installed in Module #1 and the other one will be installed in Module #2. If I'm using alignment pins, I install both of the "blind" T-nuts in Module #1. In this case, I want to use bolts to connect Module #1 to Module #2 so I'll alternate the "blind" T-nuts.

8) Repeat Steps 2 to 6 but inserting the "blind" T-nut into Module #2.

9) With the "blind" and threaded T-nuts securely installed, remove the two 1" screws that are holding the two end plates together.

The end plates should look like those shown below.

In our next blogs, we'll take a look at some Digitrax UP3/5 panels and work on some RJ12 telco jacks. This is in preparation for cutting and recessing holes in our side pieces so that we can install the Digitrax LocoNet