We've previously looked at our triangular gussets, installed some T-nuts and marked each side of the gussets as "Top" or "Bottom". In the next number of posts, we're going to work with the remaining pieces of wood that make up our module frame:

- Middle Cross-Member - the piece that's 1 1/2" wide, 3/4" thick, and 22 1/2" long.

- End Plates - the two pieces that are 3 1/2" wide, 3/4" thick, and 22 1/2" long.

- Side Pieces - the two pieces that are 3 1/2" wide, 3/4" thick, and 48" long.

As we go through the next steps, we'll be marking our pieces as "In" or "Out", "Top" or "Bottom" with a Sharpie marker.

For our End Plates and our Side Pieces, we'll refer to the 3/4" wide part as the "edges" - as in "Top" edge or "Bottom" edge. And we'll refer to the 3 1/2" wide parts as the "In" side or the "Out" side.

I can't stress enough the importance of marking each piece of wood. A few minutes spent marking each piece is going to save us grief later on.

Getting The Best Edge On "Top" And The Worst Edge On The "Bottom"

The idea here is to make sure we've got the best 3/4" edge on the top. Once we've decided, we'll mark each of the 3/4" sides of each piece of wood as "Top" and "Bottom".

If both of the 3/4" edges are nice and straight, it's a simple matter of flipping a coin and marking that edge as "Top" (on both sides) and the other edge (on both sides) as "Bottom". If one of the 3/4" edges bows up and the other edge bows down, then the edge that bows up (carpenters call it the crown) is the "Top".

Getting the Best Side "Out" And The Worst Side "In"

In getting the best of the 3 1/2" sides of our wood on the "Out" side, there are two things we have to consider.

The idea here is to make sure we've got the best 3/4" edge on the top. Once we've decided, we'll mark each of the 3/4" sides of each piece of wood as "Top" and "Bottom".

If both of the 3/4" edges are nice and straight, it's a simple matter of flipping a coin and marking that edge as "Top" (on both sides) and the other edge (on both sides) as "Bottom". If one of the 3/4" edges bows up and the other edge bows down, then the edge that bows up (carpenters call it the crown) is the "Top".

Getting the Best Side "Out" And The Worst Side "In"

In getting the best of the 3 1/2" sides of our wood on the "Out" side, there are two things we have to consider.

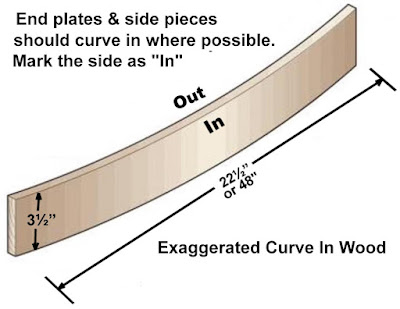

Firstly, wood has a tendency to "cup" or "crown" along the wood grain as shown in the exaggerated graphic below.

Secondly, wood has a tendency to curve "In" or "Out" along it's length. For our 48" side pieces and our 22 1/2" end plates, we want the curves to curve "In".

For our 48" side pieces, we want curves swinging into the middle of the module as our middle cross member and the gussets will "push" the curve out.

For our 48" side pieces, we want curves swinging into the middle of the module as our middle cross member and the gussets will "push" the curve out.

For our 22 1/2" end plates, our alignment bolts or clamps will pull the adjoining modules together. We can also do some sanding of each end so that we can minimize any curves.

We may find that the cupping conflicts with the curving. The curving is easy to fix whereas the cupping is more difficult. Given the choice between cupping and curving, the cupping will take priority. Cupping will be on the "Out" side.

If the wood has blemishes, gouges, or knots, the can usually be fixed with some plastic wood or epoxy before we start assembling the pieces. If it's going to be difficult fixing these, we want these to be on the "In" side, keeping in mind that cupping takes priority over all.

Once we've decided, we'll mark each 3 1/2" side of each piece of wood as "In" (as in "Inside") and "Out" (as in "Outside") using the above criteria. When we've marked our pieces of wood, they should look like the pieces below.

The end plates will be butted up against other modules in a setup so it's very important that we get the "best" sides on the top and on the outside.

If the wood has blemishes, gouges, or knots, the can usually be fixed with some plastic wood or epoxy before we start assembling the pieces. If it's going to be difficult fixing these, we want these to be on the "In" side, keeping in mind that cupping takes priority over all.

Once we've decided, we'll mark each 3 1/2" side of each piece of wood as "In" (as in "Inside") and "Out" (as in "Outside") using the above criteria. When we've marked our pieces of wood, they should look like the pieces below.

The end plates will be butted up against other modules in a setup so it's very important that we get the "best" sides on the top and on the outside.

Middle Cross Member

Let's next take a look at the 1 1/2"x 3/4"x 22 1/2" middle cross member. It's installed on the underside of our module frame and is going to serve a number of purposes.

Firstly, our modules are going to be lifted in and out of our vehicles, carted up and down stairs, and man-handled from one end of the hall to the other. The middle cross-member is going to provide extra ruggedness to our modules so as to withstand all kinds of rough treatment.

Secondly, as we build our modules, the sides may bend in or out so the middle may vary between 22 3/8" and 22 5/8". The middle cross-member will keep the middle of the module at 22 1/2". For a 4' module, I use one cross-member. For a 6' module, I use two cross-members.

Thirdly, we'll be running some wires (called the track power buss and track feeder wires) and telephone cables (called the LocoNet) on the underside of our modules. We need to keep them neatly tucked into place. If we cut a notch into the middle-cross member, we can now thread these wires and cables through the notch. (More on the wiring and fastening them to the underside of the module later on).

The notch in the middle of the cross member are a series of cuts so that we end up with a notch that's 1/2" wide and 1/4" deep in the middle of the 1 1/2"x 3/4"x 22 1/2" middle cross-member". How you cut it out will depend on the tools you have (hand saw, table saw, chisel, etc). The notch will go next to the Styrofoam. To make sure we install the cross-member properly, we mark the side that has the notch as "Top".

Here's an exaggerated graphic of that middle cross member to give you a better idea of what we've been talking about.

And here's a photo of what our middle cross member actually looks like.

Next up, we locate and drill the holes for the screws.

No comments:

Post a Comment