- to fasten legs to the bottom of the modules,

- to bolt a pair of modules together with two pieces of plywood (I call them "carry plates"), and

- to bolt a pair of modules together so we don't have to use clamps.

Let's familiarize ourselves with the parts of a T-nut so that we all understand what I'm talking about. We'll be using T-nuts that will accept a 5/16" threaded bolt.

- the barrel fits into a 3/8" hole we drill into the wood.

- the spurs are pulled into the wood as we install the T-nut.

- 5/16" bolts screw into the threaded part of the T-nut.

The Tools, Supplies & Materials For Installing T-Nuts

Here's the list of tools, materials, and supplies we'll need to have close at hand when we install the T-nuts. We'll be using this same method a couple of more times when we install the T-nuts for the carry-plates and for bolting our modules together.

In the photo above, left to right, top to bottom, we have

Before we use the bolt, we're going to give it a wipe with varsol and another wipe with varsol after each use. We don't want the bolt stuck halfway in the T-nut because some epoxy decided to harden before we were able to unscrew the bolt.

As we torque the bolt into the T-nut, epoxy will squeeze out from underneath the head of the T-nut. We'll spread this around with our skewer.

I've gathered all of these items together in one place within easy reach cause once we start to mix and apply the epoxy, things will move really fast.

Mixing The Epoxy & Installing The T-nuts

Now that we've gathered all the supplies in one spot, we're ready to start installing the T-nuts into the corner gussets.

Here's the list of tools, materials, and supplies we'll need to have close at hand when we install the T-nuts. We'll be using this same method a couple of more times when we install the T-nuts for the carry-plates and for bolting our modules together.

In the photo above, left to right, top to bottom, we have

- Varsol (turps, paint thinner, etc) for cleaning the epoxy off our fingers between installs. Also for cleaning excess epoxy off of the wood. (Canadian Tire sells an "odourless" varsol in a quart/litre can. It may also be available at your local building supply store.)

- Shop rag to be used in conjunction with the varsol.

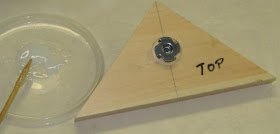

- Corner gussets with the holes drilled and marked "Top" (the underside is marked "Bottom").

- 1/2" wrench (or socket & ratchet, etc) that fits over the bolt head next to it. Make sure it fits!

- 5/16"x 1" bolt with 5/16" fender washer (or similar kind of washer) used to torque the T-nuts into the holes in the gussets.

- A supply of 5/16" T-nuts. Make sure the 5/16" bolt screws easily into each T-nut!

- Wooden shishkebab skewer (nail, rod, or other suitable item) to apply epoxy to the barrel of the T-nut.

- Epoxy resin & hardener. I use 5-minute epoxy. It mixes nice and thick and doesn't drip all over the place.

- Plastic lid (cardstock, etc) to mix the resin and hardener on.

- Underneath it is some wax paper so that the mess is easy to clean up.

Before we use the bolt, we're going to give it a wipe with varsol and another wipe with varsol after each use. We don't want the bolt stuck halfway in the T-nut because some epoxy decided to harden before we were able to unscrew the bolt.

As we torque the bolt into the T-nut, epoxy will squeeze out from underneath the head of the T-nut. We'll spread this around with our skewer.

I've gathered all of these items together in one place within easy reach cause once we start to mix and apply the epoxy, things will move really fast.

Mixing The Epoxy & Installing The T-nuts

Now that we've gathered all the supplies in one spot, we're ready to start installing the T-nuts into the corner gussets.

Step 1) Soak the shop rag in varsol. We'll need it to clean off the excess epoxy from the wood and to clean our fingers.

Step 2) Squeeze equal gobs of resin and hardener onto the plastic lid. Mix it well with the skewer.

Step 4) Insert the T-nut into the drilled hole on the "Top". You'll have to hold it in place with your finger while you insert the bolt into the hole in the "bottom"

Step 5) While you hold the T-nut in place with one hand, insert the bolt and fender washer into the hole on the "bottom" side.

Step 6) Screw the bolt in all the way until it's finger-tight.

Step 7) Torque the bolt down with the 1/2" wrench. As you torque the bolt down, it will draw the spurs of the T-nut into the wood. Tighten the bolt until it's really snug and tight.

Step 8) Unscrew and remove the bolt and the fender washer.

Step 9) As we tighten the bolt, excess epoxy will ooze out from under the top of the T-nut. Spread this around with the skewer so that we fill the gaps between the edges of the T-nut and the 1" recessed hole.

Step 10) Wipe off any epoxy that spills over the edge of the hole with the shop rag soaked in varsol.

Step 11) Repeat Steps 1) to 9) for the other gussets and T-nuts.

Step 12) Let the epoxy set for at least 24 hours.

Step 2) Squeeze equal gobs of resin and hardener onto the plastic lid. Mix it well with the skewer.

Step 3) Next, load the barrel of the T-nut with epoxy, taking care not to get any inside the threaded part. Make sure to put on lots of epoxy as we want the glue to squeeze out from underneath the washer part of the T-nut so as to securely hold the T-nut in place.

Step 4) Insert the T-nut into the drilled hole on the "Top". You'll have to hold it in place with your finger while you insert the bolt into the hole in the "bottom"

Step 5) While you hold the T-nut in place with one hand, insert the bolt and fender washer into the hole on the "bottom" side.

Step 6) Screw the bolt in all the way until it's finger-tight.

Step 7) Torque the bolt down with the 1/2" wrench. As you torque the bolt down, it will draw the spurs of the T-nut into the wood. Tighten the bolt until it's really snug and tight.

Step 8) Unscrew and remove the bolt and the fender washer.

Step 9) As we tighten the bolt, excess epoxy will ooze out from under the top of the T-nut. Spread this around with the skewer so that we fill the gaps between the edges of the T-nut and the 1" recessed hole.

Step 10) Wipe off any epoxy that spills over the edge of the hole with the shop rag soaked in varsol.

Step 11) Repeat Steps 1) to 9) for the other gussets and T-nuts.

Step 12) Let the epoxy set for at least 24 hours.

If there's any wood inside our 1" recessed hole that hasn't been covered with epoxy, I go back and apply more epoxy between the T-nut and the recess. This prevents the T-nut from turning if someone tries to torque the leg in too hard.

Once I get going, installing T-nuts into gussets is an assembly line process. I usually end up with a supply of 16-24 gussets ready for installation in the next set of modules I make.

No comments:

Post a Comment